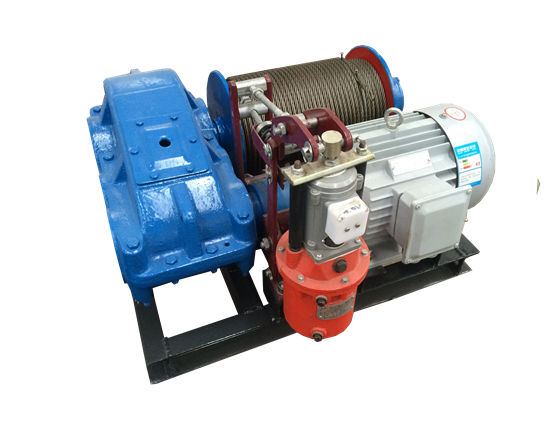

The industrial electric winch is driven by the motor. It is widely used because of its simple operation, large amount of rope and convenient displacement. It is mainly used in building, hydraulic engineering, forestry, mining, wharf, etc.

The parts of industrial electric winch

The motor is an important part of the winch and also the most expensive part in the winch. If damaged, the repair or replacement cost will be very high. So here we remind customers to take care of the winch or winch motor. The maintenance method is as follows:

Winch Parameter:

Loading capacity: 1t—-200 t

Wire rope capacity: 20—-3600 m

Working speed: 5—-35 m/min;

Power supply: 50/60HZ,3Phase

Customized according to your requirements.

Get a Free Quote

1. The environment should be kept dry frequently, and the surface of the motor should be kept clean. The inlet should not be blocked by dust or fiber.

2. When the motor’s thermal protection occurs continuously, it should be found out that the fault comes from the motor or the overload or protection device setting value is too low, and after the fault is eliminated, the operation can be put into operation.

3. The motor should be well lubricated during operation.

The general electric motor runs about 5000 hours, namely should replenish or replace the grease, when the bearing is overheated or lubricated, the hydraulic pressure changes the grease in time. Replacing grease, should clean up the old oil, and gasoline wash oil bearing and the bearing cover, then put the ZL – 3 lithium base grease filling bearing between the inner and outer ring cavity 1/2 (2) and two-thirds (4, 6, 8).

AQ-JM Type Winch

Loading capacity: 0.5~200 t;

Wire rope capacity: 20~3600 m;

Working speed: 5~20 m/min;

Power supply: 220-690V,50/60HZ,3Phase;

4. When the life of the bearing is finished, the vibration and noise of the motor will increase significantly. When the radial clearance of the bearing reaches the following value, the bearing shall be replaced.

5. When the motor is removed, the rotor can be removed from either the shaft or the non-extension end.

6. If it is not necessary to remove the fan, it is more convenient to remove the rotor from the non-shaft end. When the rotor is drawn out of the stater, it should be prevented from damaging the stater winding or insulation.

7. Replacing winding must take note of the original winding form, size and number of turns, wire gauge, etc., when the data lost, should be to the factory, change the original design winding, often worsen or a few of the motor performance, even not be able to use.

Features of our industrial electric winch

1.The winch machine provided by our company has good quality and competitive price;

2.The heavy duty winch can offer heavy lifting and puling force and different capacity as needed;

3.The hydraulic winch equip with reliable braking and control units;

4.The hydraulic winch machine can be used on different occasions for diverse applications and conditions;

5.Our winches have compact structure and reasonable design;

6.The construction winch is easy to install, operate and maintain;

7.The industrial electric winch works reliably with low noise.

AQ-JK Type Winch

Loading capacity: 0.5~60 t;

Wire rope capacity: 20~500 m;

Working speed: 20~35 m/min;

Power supply: 220-690V,50/60HZ,3Phase;

Perfect after-sale service by us

1.Our professional engineers are ready to go abroad for installation, commissioning, instruction and maintenance whenever necessary;

2.We offer free training and guidance of operation and maintenance in our factories as clients need;

3.We also have free training and guidance for the clients’ service and maintenance staff about installing, debugging, operating or maintaining the winch machine;

4.We provide the perfect service to make sure that the industrial electric winch you purchase from us work effectively and reliably all the time during its service life.

AQ-JMM Type Winch

Loading capacity: 0.5~100t;

Wire rope capacity: 20~5000 m;

Working speed: 5~20 m/min;

Power supply: 220-690V,50/60HZ,3Phase

AQ-JKL Type Winch

Loading capacity: 1~10t;

Wire rope capacity: 20~500 m;

Working speed: 20~36 m/min;

Power supply: 220-690V,50/60HZ,3Phase;

Safe operation of industrial electric winch

1. The operator must be familiar with the mechanical properties, construction and operation methods. To hold the operation certificate issued by the labor bureau.

2. Before operation, check the anchor of the hoisting machine, whether the loading rack is firm, and check whether the clutch and brake are sensitive and reliable. Exposed belt, gear and other transmission devices, whether the protective cover is complete.

3. The wire rope should be arranged neatly. In the process of lifting the crane, at least 3~5 laps should be kept on the drum, and the wear degree of the wire rope should not exceed 10%, and the steel wire rope of the pulley can’t be connected.

4. The winch should be used and maintained by special people, and check whether the grounding circuit is in good condition. If the electrical equipment is found to be leaking or other faults, it should report to the fore in time. No unauthorized repair.

5. The hoisting basket must be equipped with a safety door, which can only lift the material and strictly prohibit carrying people. The crane stays in the air, except for the brake, and also with a parking rack. It is strictly forbidden to walk under the crane on the wire rope.

6. The loading rack must have good grounding and lightning protection devices. Check whether the limiter is flexible and reliable once a week. When lifting heavy objects, the bricks and ashes should not exceed 0.5 tons. It is strictly forbidden to transport overweight or long articles.

7. Power supply should be cut off when there is a power failure in the operation. Lowered the object or crane to the ground.

8.After the operation is completed, the hoisting of the crane or object should be lowered to the ground, and the power supply should be cut off and the switch box should be locked.

More details about industrial electric winch

For more information about how to choose suitable industrial electric winch and how to keep it in good conditions, contact us to know further about our products. We produce hydraulic and electric winch with high quality which can ensure its high sufficiency and long term use for lifting and pulling operations. Our company has produced and customized winch machines for a long time and has clients all over the world. What’s more, the clients have been satisfied with our products since they purchased the hydraulic or electric winch, and some of them have cooperated with us again and ordered more products from us. No matter you want to select small one or to buy huge one, you can just get the right and quality one with very reasonable price.