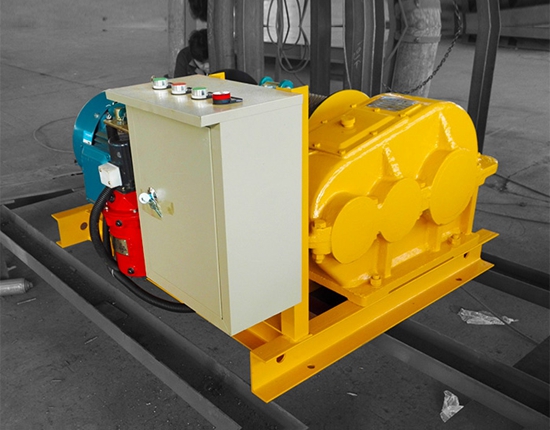

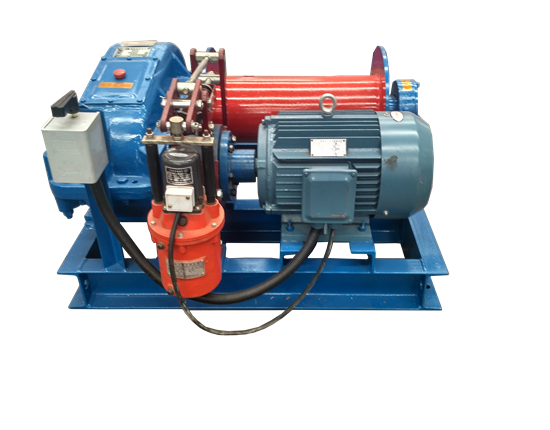

Construction winch is in the land for use in a variety of projects of all kinds of electric industrial winch (also can be customized hydraulic hoist and diesel type winch), used to enhance or pull. They mainly includes: AQ-JM slow construction winch, AQ-JK fast construction, AQ-JKL humping fast construction winch, AQ-JKD planet type construction winch, AQ-JMM friction construction winch and some customized for mine industrial winch. Our company pays attention to the quality of winches, such as drum, winch rope, motor, to ensure best quality.

Parts and types of construction winch

Winch Parameter:

Loading capacity: 1t—-200 t

Wire rope capacity: 20—-3600 m

Working speed: 5—-35 m/min;

Power supply: 50/60HZ,3Phase

Customized according to your requirements.

Get a Free Quote

A small lifting device used to hoist a steel wire rope or chain or lift equipment with heavy weight. The winch can lift vertically, horizontally or tilt the weight. The industrial winch is divided into manual industrial winch and electric construction winch. Now it is dominated by electric winch. It can be used alone, and it can also be used for lifting, building roads and mine hoisting machinery. It is widely used because of its simple operation, large amount of rope and convenient displacement. It is mainly used in building, hydraulic engineering, forestry, mining, wharf, etc. Construction winch mainly consists of the following parts: motor, triangle belt, transmission shaft, gear, reel, steel wire rope, fixed pulley, movable pulley, crane hook, brake, bearing, etc.

The choice of winch rope

Why should the construction use wire rope in lifting operation, because it is necessary to bind and pull the object, and it is necessary to have flexible elements to complete. The commonly used flexible elements are wire rope, hemp rope, harness and chain, etc. Wire rope compared with other flexible components, has high flexible and elastic carrying capacity, good abrasion resistance, impact resistant, reliable work, in high speed motion without noise and the use of durable wait for an advantage. Therefore, in lifting operation, steel wire rope has been widely used.

Winch Parameter:

Loading capacity: 1t—-200 t

Wire rope capacity: 20—-3600 m

Working speed: 5—-35 m/min;

Power supply: 50/60HZ,3Phase

Customized according to your requirements.

Get a Free Quote

The steel wire rope of common type industrial winch is the same steel wire with the same diameter and the six strands with an oily organic cord heart (flax heart or cotton heart). If the number of steel wire per share is 19, it can be represented by 6×19. If the number of steel wire is 37, it can be seen in table 97(a) of 6x 37. The composite copper wire rope is made of six or more strands of steel wire with different diameters and an organic cord heart or an inorganic cord. The method is the same as ordinary steel wire rope, as shown in FIG. 97(b). The steel wire rope of the closed type industrial winch is made of the outer wire, and the inner package is a wire with a diameter, and the special method is used to twist it. In the hoisting operation, the application is more common and composite wire rope.

Wire rope of the construction winch

The wire rope should be drawn from the bottom of the drum. The wire rope on the tube should be arranged in order, and should be kept at least 5 times when working. The outermost wire rope should be lower than the diameter of a wire rope.

There are two common fixing methods: one is a wedge hole in the winch, and the wire rope is fixed in the hole through a wedge joint. The other is to have holes in the side baffle of the industrial winch drum, and the steel wire rope’s head is worn out and the screw is pressed to the outside of the side plate of the drum. Other methods have not been seen for the time being.

AQ-JK Type Winch

Loading capacity: 0.5~60 t;

Wire rope capacity: 20~500 m;

Working speed: 20~35 m/min;

Power supply: 220-690V,50/60HZ,3Phase;

Safety requirements

1.Set up the operating shed and ensure that the operator can see the conductor and the objects that are dragging or lifting. The construction, scaffolding and site stacking materials, components and so on shall not affect the driver’s monitoring of the whole process within the operation scope. Operating tents in hazardous operating areas shall meet the requirements of the protective shelter at the top.

2. Solid foundation.

Industrial winch should as far as possible away from dangerous operations area, choose the higher ground, soil solid, buried anchor winch wire rope and hoist fastens its seat. The front should be piling, prevention and control of hoist movement and capsized.

3. Drum direction.

For drum and guide pulley center, the distance from the drum to the first guide pulley, according to the rules is: grooved drum should be more than 15 times of the width of the reel, slot-less reel should be more than 20 times, in order to prevent the drum steel wire rope fault fold each other during operation and guide wheel flange and steel wire rope wear.

Our construction winch for sale

We design construction winch lifting and transporting something with heavy weight according to per customers’ demands. The lifting and transporting industrial winch provided by us are with top quality because Amix Group control the quality from the source material and easy installation and operations. And they can work efficiently and reliably. The industrial winch can be designed with different tonnages of capacity, different steering mode of moving, etc. We also provide free training for safe installing and operating. If you need such kind of construction for your work, just contact us, you will get a range of options for your working demands.